Are Office Chair Bases Universal? The Complete Compatibility Guide

Have you ever tried to replace a broken office chair base, only to discover that the new one doesn’t fit? Or perhaps you’ve wondered if you could upgrade your wobbly plastic base to a sturdier metal one without buying an entirely new chair? You’re not alone in this frustration, and the answer to whether office chair bases are universal might surprise you.

No, office chair bases are not completely universal. While there are industry standards that many manufacturers follow, office chair bases vary in diameter, material, weight capacity, and connection mechanisms. However, with the right measurements and knowledge, you can often find compatible replacements across different brands and models.

This comprehensive guide will walk you through everything you need to know about office chair base compatibility, from understanding standard measurements to identifying which bases will work with your specific chair. Whether you’re looking to repair a beloved chair or upgrade to a more durable base, you’ll learn exactly what to look for and how to avoid costly mistakes.

By the end of this article, you’ll understand:

•The standard measurements most office chair bases follow

•How to determine if a replacement base will fit your chair

•Which brands use compatible or interchangeable bases

•Common compatibility issues and how to solve them

•Step-by-step guidance for measuring and replacing your chair base

Let’s dive into the world of office chair bases and unravel the mystery of their compatibility once and for all.

Understanding Office Chair Base Fundamentals

What Defines an Office Chair Base?

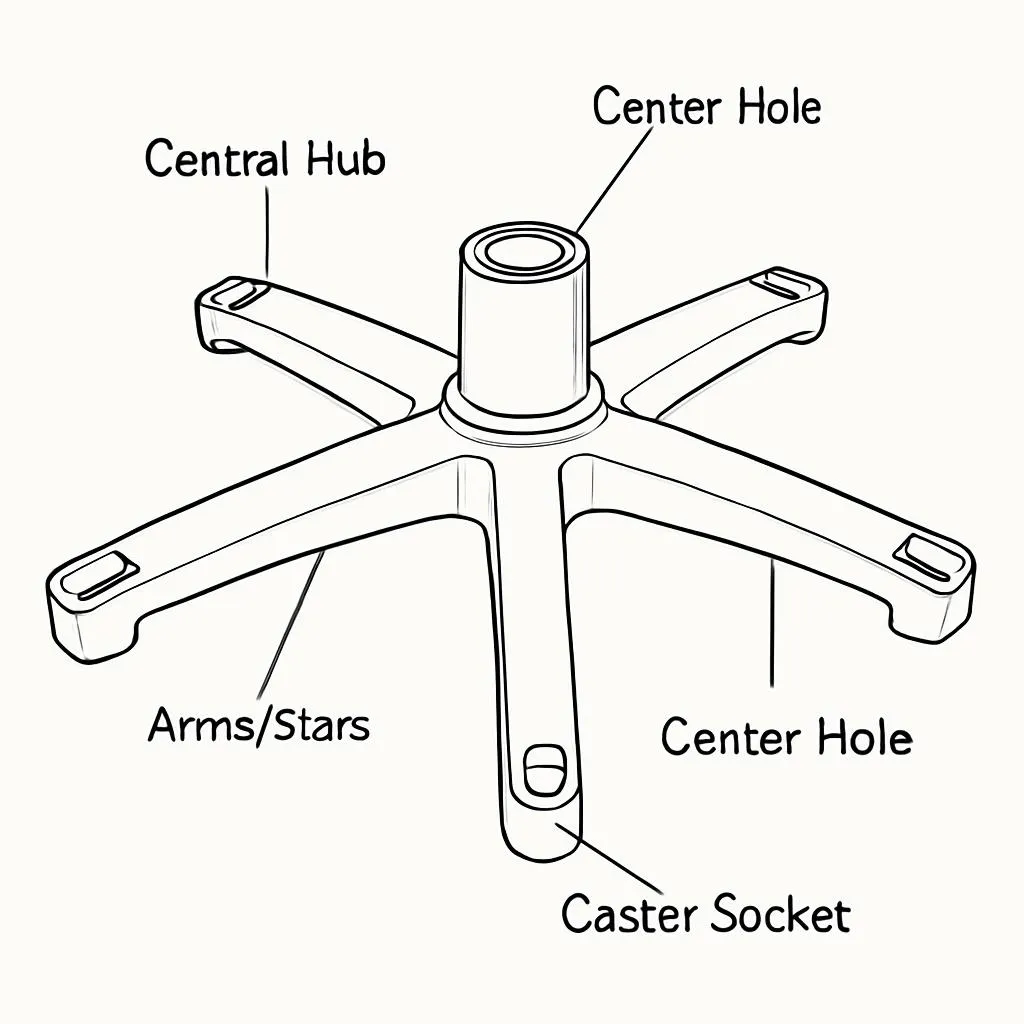

An office chair base is the foundational structure that supports the entire chair and connects to the floor. It serves three critical functions: providing stability, enabling mobility, and supporting the weight of both the chair and its occupant. The base is the unsung hero of your office chair—when it works well, you hardly notice it, but when it fails, the entire chair becomes unusable.

Most modern office chair bases consist of several key components working together. The central hub connects to the gas cylinder (the mechanism that allows height adjustment), while the arms or “stars” extend outward to provide stability. At the end of each arm, you’ll typically find either casters (wheels) for mobility or glides for stationary use.

The design and quality of your chair base directly impact not only the chair’s stability and durability but also its safety. A poorly designed or damaged base can lead to tipping, structural failure, and potential injury—making proper understanding of these components essential for anyone looking to replace or upgrade their chair base.

Common Types of Office Chair Bases

Office chair bases come in several standard configurations, each designed for specific applications and weight capacities:

Five-Star Bases: The most common design for office task chairs, featuring five arms extending from the central hub. This design provides optimal stability and weight distribution, making it the industry standard for most office environments. The five-point design effectively prevents tipping even when users lean in different directions.

Four-Leg Bases: More commonly found on guest chairs, dining chairs, or specialized task stools. While less stable than five-star designs, they offer a smaller footprint and can be appropriate for lighter-use scenarios or where space is limited.

Cantilever Bases: Used primarily in specialized seating like drafting stools or certain ergonomic designs. These bases feature a different weight distribution system and are less common in standard office chairs.

Sled Bases: Found on some guest chairs and waiting room seating, these bases have a continuous frame that contacts the floor along its length rather than at specific points.

Standard Materials Used in Chair Bases

The material of your office chair base significantly affects its durability, weight capacity, and price point. Here are the most common materials used:

Nylon/Reinforced Plastic: The most affordable and lightweight option, these bases are common in budget to mid-range office chairs. Quality varies significantly—premium reinforced nylon can support substantial weight (up to 250-300 pounds), while basic plastic bases may crack under less pressure. These bases typically have a matte black finish and are relatively resistant to scratches.

Aluminum: The mid-range option that balances durability with weight. Aluminum bases are significantly stronger than plastic, resist corrosion, and can support heavier weights (typically 300-400 pounds). They come in various finishes, including polished, brushed, or painted, making them popular for both functional and aesthetic reasons.

Steel: The heaviest and typically most durable option. Steel bases can support the highest weight capacities (often 400+ pounds) and are extremely resistant to damage. However, they add significant weight to the chair and may be susceptible to rust if the finish is damaged.

Wood: Less common in standard office chairs but found in some designer or executive models. Wood bases offer a distinctive aesthetic but generally provide less adjustability and may have lower weight capacities than their metal counterparts.

Office Chair Base Standardization and Measurements

Industry Standard Measurements

While office chair bases aren’t completely universal, the industry has developed certain standard measurements that many manufacturers follow. Understanding these standards is crucial when considering replacement or compatibility:

Center Hole Diameter: The most critical measurement for compatibility is the diameter of the center hole where the gas cylinder inserts. The most common standard is approximately 2 inches (50mm) in diameter, though some heavy-duty chairs use a larger 2.75-inch (70mm) opening. This measurement largely determines whether a replacement base will fit your existing chair’s cylinder.

Overall Diameter: The total span of the base from arm tip to arm tip typically ranges from 22 inches to 28 inches. Standard task chairs often use a 24-26 inch base, while heavy-duty or executive chairs may use larger 27-28 inch bases for additional stability. Larger bases generally provide better stability but require more floor space.

Arm Length: The length of each arm or star from the center to the tip affects both stability and the chair’s footprint. Standard measurements range from 10-14 inches, with longer arms providing greater stability at the cost of requiring more space.

Caster Socket Size: The standard size for caster stem grip rings (the part that inserts into the base) is typically 7/16″ x 7/8″ (11mm x 22mm), though some manufacturers use proprietary sizes.

How to Measure Your Chair Base Correctly

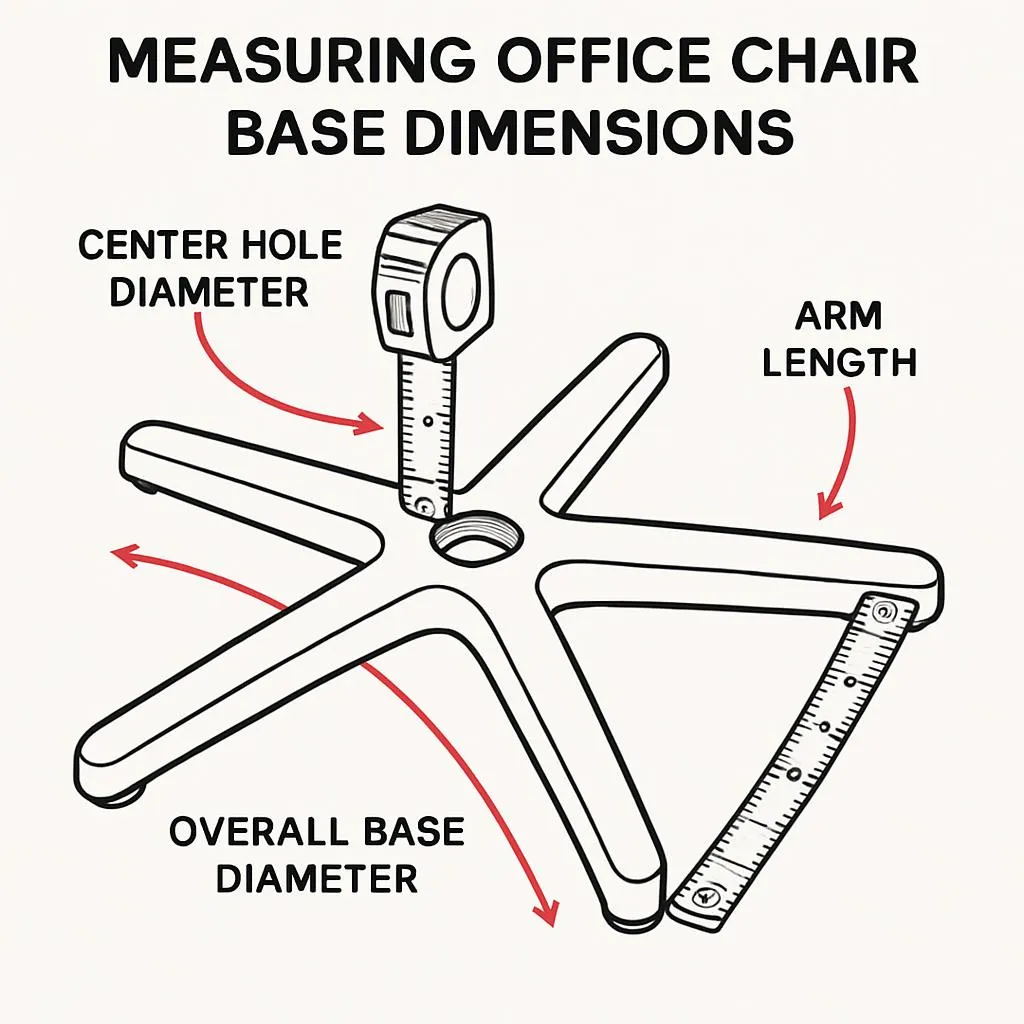

Accurate measurements are essential when determining compatibility for replacement. Here’s how to properly measure your chair base:

1.Center Hole Diameter: Remove the gas cylinder from the base (if possible) and measure the inner diameter of the hole. If you cannot remove the cylinder, measure the outer diameter of the cylinder where it enters the base.

2.Overall Diameter: Measure from the tip of one arm to the tip of the opposite arm, going through the center. For the most accurate assessment, take measurements between multiple arms.

3.Arm Length: Measure from the center of the base to the tip of one arm. Check multiple arms to ensure consistency.

4.Caster Socket Size: Measure both the diameter and depth of the caster socket holes at the end of each arm.

5.Weight Capacity: Check the underside of your chair or the manufacturer’s documentation for weight capacity information. Any replacement base should match or exceed this rating.

Regional Differences in Standards

It’s worth noting that chair base standards can vary somewhat between regions:

North American Standards: Typically use imperial measurements and follow BIFMA (Business and Institutional Furniture Manufacturer’s Association) guidelines for stability and durability.

European Standards: Often use metric measurements and adhere to EN standards for office furniture.

Asian Manufacturing: Many chairs are now manufactured in Asia, particularly China, which generally follows international standards but may have slight variations in some measurements.

These regional differences rarely prevent compatibility entirely but may require adapters or slight modifications in some cases.

Compatibility Factors Between Chair Bases

Gas Cylinder Compatibility

The gas cylinder (also called a pneumatic cylinder or gas lift) is the component that connects the chair base to the seat mechanism and allows height adjustment. Cylinder compatibility is perhaps the most critical factor when considering base interchangeability:

Standard Cylinder Sizes: Most office chairs use cylinders with a tapered end that fits into the chair base. The standard taper size is approximately 2 inches (50mm) in diameter, though heavy-duty chairs may use larger 2.75-inch (70mm) cylinders.

Cylinder Classes: Gas cylinders come in different classes based on their stroke length (how much height adjustment they provide) and weight capacity. Class 2, 3, and 4 are the most common for office chairs, with Class 4 being the standard for most task chairs.

Proprietary Designs: Some manufacturers, particularly those producing high-end ergonomic chairs, use proprietary cylinder designs that may not be compatible with standard bases.

When replacing a chair base, you must ensure that the new base’s center hole can accommodate your existing cylinder. If not, you may need to replace both components together.

Weight Capacity Considerations

Weight capacity is a crucial safety factor that is often overlooked when replacing chair bases:

Standard Task Chairs: Typically designed to support 250-275 pounds.

Heavy-Duty Chairs: Can support 300-500+ pounds, depending on the specific design and materials.

Material Impact: Nylon bases typically support lower weights than aluminum or steel bases of the same design.

Safety Margins: Manufacturers build in safety margins, but exceeding the rated weight capacity significantly increases the risk of failure.

Using a base with a lower weight capacity than your chair is designed for can lead to premature failure, potential injury, and will likely void any remaining warranty on the chair.

Caster Socket Compatibility

The connection between the base and the casters is another important compatibility factor:

Standard Grip Ring Size: Most office chair bases use a 7/16″ x 7/8″ (11mm x 22mm) socket for casters, though some manufacturers deviate from this standard.

Stem Types: Casters come with different stem types, including grip ring (most common), threaded, and stem-less designs. The base must have sockets designed for the specific stem type.

Hardwood vs. Carpet Casters: While not directly related to base compatibility, it’s worth noting that different caster types are designed for different flooring surfaces. When replacing a base, consider whether you need to update your casters as well.

If your replacement base has different caster sockets than your existing casters, you may need to purchase new casters that are compatible with the new base.

When Chair Bases Are Interchangeable

Common Scenarios Where Bases Can Be Swapped

Despite the variations in chair base designs, there are many scenarios where interchangeability is possible:

Standard Task Chairs: Many standard office task chairs from different manufacturers use similar base specifications, particularly those in the mid-range market segment. If both chairs use the standard 2-inch cylinder connection and have similar weight ratings, their bases can often be swapped.

Same Manufacturer, Different Models: Chairs from the same manufacturer, especially within the same product line or price point, frequently use identical or compatible bases even if the chairs look different above the base.

Aftermarket Replacements: There is a robust market for universal replacement bases designed specifically to fit a wide range of chair models. These typically accommodate standard cylinder sizes and include adapters for minor variations.

Upgrading Materials: One of the most common successful swaps is upgrading from a plastic base to an aluminum or steel base of the same size and configuration. This can extend the life of an otherwise good chair and increase its weight capacity.

Brand-Specific Compatibility

Some brands are known for better cross-compatibility than others:

Herman Miller: Many Herman Miller task chairs use standardized bases within their product lines, though their high-end ergonomic chairs often use proprietary components.

Steelcase: Similar to Herman Miller, Steelcase maintains some standardization within product families but uses proprietary designs for their premium models.

HON/Global/Eurotech: These mid-range manufacturers tend to use more standardized components, making their bases more likely to be interchangeable with other brands.

Gaming Chair Brands: Many gaming chair manufacturers use similar base designs, making cross-compatibility relatively common within this specific market segment.

It’s always advisable to check with the manufacturer or a knowledgeable dealer before attempting to swap bases between different brands or models.

Universal Replacement Options

The aftermarket for chair parts has responded to the need for replacement bases with several universal options:

Adjustable Center Holes: Some replacement bases feature adjustable or multi-size center holes that can accommodate different cylinder diameters.

Adapter Kits: These kits include spacers and adapters that allow bases to work with cylinders of varying sizes.

Heavy-Duty Universal Replacements: These bases are designed with reinforced materials and larger dimensions to safely replace almost any standard office chair base.

DIY Modifications: With the right tools and knowledge, minor modifications can sometimes be made to achieve compatibility between otherwise incompatible components.

Universal replacements typically cost more than exact model matches but offer the convenience of not having to identify the precise specifications of your original base.

When Chair Bases Are NOT Interchangeable

Proprietary Designs and Why Manufacturers Use Them

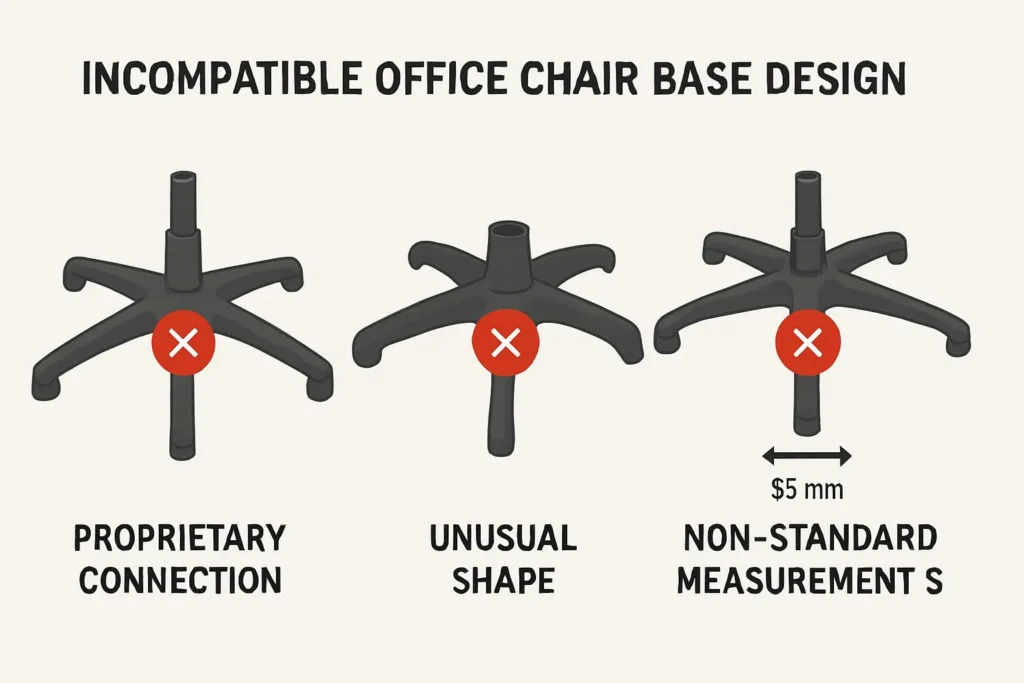

Some chair manufacturers intentionally use proprietary base designs that prevent easy interchangeability:

Brand Protection: Proprietary designs ensure customers must return to the original manufacturer for replacement parts, protecting the company’s aftermarket sales.

Specialized Engineering: High-end ergonomic chairs often feature unique mechanisms that require specially designed bases to function properly.

Aesthetic Considerations: Designer and executive chairs may use distinctive base designs as part of their visual appeal, prioritizing appearance over standardization.

Integrated Technology: Some modern chairs incorporate technology into the base, such as charging ports or electronic controls, necessitating proprietary designs.

Chairs from manufacturers like Herman Miller (Aeron, Embody), Steelcase (Gesture, Leap), and HÅG often feature proprietary base designs that cannot be easily replaced with universal options.

Special Cases: Gaming Chairs, Executive Chairs, and More

Certain chair categories are particularly prone to compatibility issues:

Gaming Chairs: Despite similarities within the gaming chair market, these chairs often use bases with unique aesthetic features or specialized weight distribution that aren’t compatible with standard office chair bases.

Executive Chairs: High-end executive chairs frequently feature distinctive bases made from premium materials like polished aluminum or wood that are integral to the chair’s design and not easily replaceable.

Specialized Ergonomic Chairs: Chairs designed for specific ergonomic needs, such as kneeling chairs, saddle seats, or balance ball chairs, use highly specialized bases that rarely interchange with standard designs.

Vintage or Antique Office Chairs: Older chairs often predate modern standardization efforts and may use obsolete measurements or connection methods.

In these cases, replacement typically requires either an exact match from the original manufacturer or a custom solution.

Warning Signs That a Base Won’t Be Compatible

Watch for these red flags that suggest a replacement base may not be compatible with your chair:

Unusual Center Hole Size: If your chair’s cylinder is significantly larger or smaller than the standard 2-inch diameter, finding a compatible base will be challenging.

Integrated Mechanisms: If the height adjustment mechanism or tilt controls are built into the base rather than the seat, standard replacements won’t work.

Non-Standard Arm Count: Chairs with four arms or six arms instead of the standard five may require specialized replacements.

Unique Mounting System: Some chairs use bolted connections or other non-standard methods to attach the base to the cylinder.

Extremely High Weight Capacity: Chairs rated for 500+ pounds often use reinforced bases with specialized construction that standard replacements can’t match.

If you encounter any of these warning signs, consult with the original manufacturer or a specialized office furniture repair service before attempting a replacement.

Practical Guide to Replacing Your Chair Base

Step-by-Step Replacement Process

Replacing an office chair base is typically straightforward if you’ve confirmed compatibility:

1.Prepare Your Workspace: Clear a flat, spacious area and lay down a protective covering to prevent damage to floors or the chair components.

2.Turn the Chair Upside Down: Carefully flip the chair over so the base is accessible. Remove any items that might fall off during the process.

3.Remove the Casters: Pull the casters straight out from the base. If they’re stubborn, use a flathead screwdriver to gently pry them loose.

4.Separate the Base from the Cylinder:

•For most chairs: Apply penetrating oil to the connection point and let it sit for 15-30 minutes. Then, firmly tap the underside of the base around the cylinder with a rubber mallet until it separates.

•For stuck connections: You may need to use a pipe wrench to grip the cylinder while tapping the base, or in extreme cases, a chair cylinder removal tool.

5.Prepare the New Base: If your new base came with casters, ensure they’re properly inserted. If reusing your old casters, insert them into the new base.

6.Connect the New Base to the Cylinder: Align the center hole of the new base with the cylinder and press firmly until it’s fully seated. You may need to tap it with a rubber mallet to ensure a secure fit.

7.Test the Chair: Carefully turn the chair right-side up and test it for stability and function before regular use.

Tools Needed and Safety Considerations

To replace an office chair base safely and effectively, you’ll need:

Basic Tools:

•Rubber mallet

•Penetrating oil (WD-40 or similar)

•Flathead screwdriver

•Work gloves

For Difficult Removals:

•Pipe wrench

•Chair cylinder removal tool (available online)

•Heat gun (for extremely stubborn connections)

Safety Considerations:

•Wear eye protection when striking components

•Use work gloves to protect your hands

•Be cautious of the pressurized gas cylinder—never attempt to disassemble it

•Ensure the new base meets or exceeds the weight capacity of your chair

•Test the stability of the chair before full use

Where to Find Quality Replacement Bases

Quality replacement bases can be sourced from several reliable channels:

Original Manufacturer: The safest but often most expensive option. Contact the chair manufacturer’s customer service for exact replacement parts.

Office Furniture Dealers: Local dealers often stock common replacement parts or can order them for you.

Online Specialty Retailers: Websites specializing in office chair parts (like Crandall Office Furniture, Madison Seating, or Chair Parts Online) offer a wide selection of both exact and universal replacements.

General Online Marketplaces: Amazon, eBay, and similar sites carry many universal replacement bases, though quality can vary significantly.

Local Office Liquidators: These businesses often have salvaged parts from quality chairs at discounted prices.

When purchasing a replacement base, prioritize:

•Correct size specifications

•Appropriate weight capacity

•Quality materials

•Positive reviews or recommendations

•Warranty coverage

Investing in a quality replacement base can extend your chair’s life by many years, making it a worthwhile expenditure compared to purchasing an entirely new chair.

Data Tables for Quick Reference

Table 1: Comparison of Base Materials

| Material | Weight Capacity | Durability | Cost | Best For |

| Nylon/Plastic | 250-300 lbs | 3-5 years | $20-50 | Budget chairs, lightweight users |

| Aluminum | 300-400 lbs | 7-10+ years | $50-100 | Mid to high-end chairs, average to heavy users |

| Steel | 400-500+ lbs | 10+ years | $70-150 | Heavy-duty chairs, intensive use environments |

| Wood | 250-350 lbs | Varies | $100-300+ | Executive chairs, design-focused environments |

Table 2: Standard Base Measurements

| Component | Standard Measurement | Heavy-Duty Measurement | Notes |

| Center Hole Diameter | 2″ (50mm) | 2.75″ (70mm) | Most critical for compatibility |

| Overall Base Diameter | 24-26″ | 27-28″ | Larger = more stability |

| Arm Length | 10-12″ | 12-14″ | Measured from center to tip |

| Caster Socket Size | 7/16″ x 7/8″ (11mm x 22mm) | Same | Some proprietary variations exist |

| Base Height | 2-3″ | 2-3″ | Measured without casters |

Table 3: Brand Compatibility Guide

| Brand | Interchangeability | Compatible With | Notes |

| Herman Miller | Limited | Some HON, Steelcase | High-end models use proprietary bases |

| Steelcase | Limited | Some Herman Miller, HON | Leap and Gesture use proprietary designs |

| HON | Good | Many universal bases | Generally follows industry standards |

| Global | Good | Many universal bases | Generally follows industry standards |

| Gaming Chair Brands | Moderate | Other gaming chairs | Often compatible within gaming chair category |

| IKEA | Poor | IKEA only | Typically uses proprietary designs |

| Autonomous | Moderate | Universal bases | Some models use standard measurements |

Conclusion: Are Office Chair Bases Universal?

The Final Answer on Office Chair Base Universality

After exploring all aspects of office chair bases, we can definitively answer our original question: No, office chair bases are not completely universal, but they do follow certain industry standards that allow for compatibility in many cases.

The universality of office chair bases exists on a spectrum rather than as a simple yes or no. Standard task chairs often use similar measurements—particularly the critical 2-inch (50mm) center hole diameter—making many bases interchangeable across brands and models. However, high-end ergonomic chairs, gaming chairs, and executive models frequently use proprietary designs that limit compatibility.

The key to successful replacement lies in understanding the specific measurements and requirements of your chair. By properly measuring your existing base and cylinder connection, checking weight capacity requirements, and understanding caster compatibility, you can confidently select a replacement that will work with your chair.

What This Means for Your Office Chair

For the average office worker looking to repair or upgrade their chair, this mixed news is actually quite positive. You’re not limited to expensive manufacturer-specific replacements in many cases. Universal replacement bases are widely available and can often restore or even improve your chair’s functionality at a fraction of the cost of a new chair.

If you own a standard task chair from a mainstream manufacturer, you’ll likely have multiple replacement options available. If you own a high-end ergonomic chair or a chair with unusual features, you may need to work with the original manufacturer or specialized dealers to find compatible parts.

Practical Takeaways for Chair Base Replacement

Before purchasing any replacement base, remember these essential points:

1.Measure twice, buy once: Accurate measurements, particularly of the center hole diameter, are crucial for compatibility.

2.Consider weight capacity: Never downgrade to a base with a lower weight capacity than your original.

3.Check material quality: Upgrading from plastic to aluminum or steel can significantly extend your chair’s lifespan.

4.Look for warranties: Quality replacement bases often come with their own warranties, providing additional value.

5.Consider professional installation: If you’re uncertain about the replacement process or encounter difficulties, professional installation is worth the cost to ensure safety and proper function.

By understanding the nuances of chair base compatibility and following the guidelines in this article, you can make informed decisions about repairing or upgrading your office chair, potentially saving hundreds of dollars while extending the life of your seating.

Remember that a quality chair base is an investment in both comfort and safety—the foundation upon which your entire work experience rests. Choose wisely, and your office chair will continue to support you reliably for years to come.

Recommended Videos for Visual Learners

For those who prefer visual demonstrations, these YouTube videos provide excellent guidance on measuring and replacing office chair bases:

1.How to Measure Your Office Chair Base for Replacement

2.Step-by-Step Office Chair Base Replacement Guide

3.Comparing Different Types of Office Chair Bases

These resources offer practical demonstrations that complement the information provided in this article, making your replacement project even more straightforward.