You want a unique chair. The OEM steps feel confusing. You worry about mistakes and delays. I take your idea and turn it into a chair with a clear, simple path.

The OEM process for custom office chairs moves through ten steps. I guide you from idea to shipping: brief, feasibility, design, sample, revisions, contract, production, inspection, shipping, customs. You get a ready-to-sell chair.

You need a straight path with no noise. I keep each step clear, on time, and inside budget. I explain how we go from first message to your warehouse. I show what to prepare, what to check, and what to avoid. Stay with me and you will see the whole process, without guesswork.

How do we start the brief and check feasibility?

You have ideas but no factory map. You fear miscommunication. You need fast feedback and a real plan. I turn a rough concept into a clear design direction.

You contact me with your chair idea and priorities. I reply with options, cost ranges, materials, and feasibility notes. We align on goals, target price, and timeline before we go deeper.

I ask for your target users, budget, and must-have features. I share options that fit your goals. I flag risks like tooling, structure limits, or certification needs. We build a shared brief. This saves time and avoids rework.

What I need from you

- Product type: office chair, ergonomic chair, gaming chair, task chair.

- Market target: entry, mid, or premium; B2B or e-commerce.

- Price window: retail and target landed cost.

- Key features: mesh back, synchro tilt, 3D armrests, headrest, footrest.

- Look and feel: colors, textures, brand style.

What I give you

- Feasibility notes and risks.

- Mechanism and structure options with pros/cons.

- Material suggestions by budget.

- Cert paths: BIFMA, CE, RoHS, with testing plans.

- Lead-time outline and MOQ advice.

| Input From You | My Immediate Output |

|---|---|

| Use case and budget | Matching mechanisms and frames by cost tier |

| Design preferences | Material palettes and finish samples |

| Compliance needs | Test plan, timeline, and cost estimate |

| Launch deadline | Production calendar and buffer suggestions |

How do we fix the design details before sampling?

You want a beautiful chair that can be built. You fear hidden costs and vague specs. I lock every detail before we spend on a sample.

We finalize materials, functions, dimensions, and branding. I prepare a full spec sheet and drawings. You confirm them. Then I start sample production with no missing pieces.

I keep this stage simple and visual. I share photos, videos, and spec charts. You see each part, not just words. We cut guesswork and lock decisions early. This keeps the sample fast and accurate.

Key spec areas we lock

- Structure: base (nylon/steel/aluminum), gas lift class, casters size.

- Mechanism: swivel, tilt type, recline angle, lock points.

- Ergonomics: lumbar type, armrest levels, seat foam density.

- Fabrics: mesh grade, fabric weight, color code, abrasion.

- Branding: logo location, label, box artwork, barcode.

Documents you receive

- Final BOM1 and spec sheet.

- 2D drawings and part photos.

- Packaging plan and carton test standard.

- Certification route and sample test plan.

| Spec Category | Options | Notes |

|---|---|---|

| Base | Nylon / Steel / Aluminum | Cost vs strength vs look |

| Mechanism | Simple tilt / Synchro / Multi-tilt | Comfort and price impact |

| Armrests | Fixed / 2D / 3D / 4D | User segment defines choice |

| Foam | Molded / Cut | Comfort, shape, durability |

| Fabric | Mesh / Knitted / PU / Eco | Market trend and stock risk |

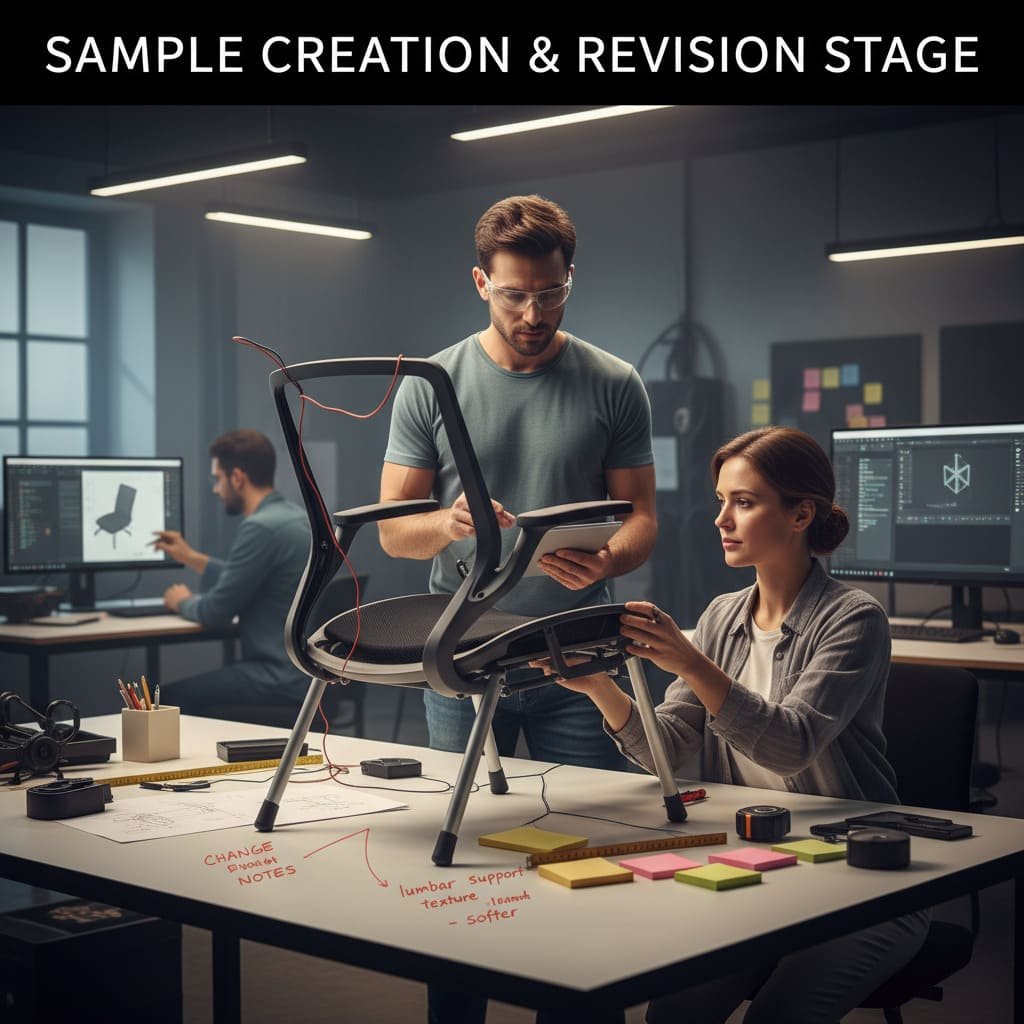

How do we create and refine the sample?

You worry the sample will miss the mark. You fear slow fixes. I build a true-to-spec sample and move fast on changes.

I make a working prototype to the approved specs. You test build, comfort, and looks. You send change notes. I refine and resample if needed until you approve.

I treat the sample like the first unit off the line. I match parts, finishes, and packaging. I record all changes in a revision log. You see photos and videos before shipment. You also get a sample QC sheet. This keeps feedback focused and clear.

How to test your sample

- Sit test: 30–60 minutes use. Check lumbar and foam recovery.

- Function test: height, tilt, armrest, recline, lock.

- Noise check: squeaks and friction points.

- Finish check: color match, stitching, paint texture.

- Assembly check: tools, time, instruction clarity.

Common refinements

- Foam hardness up or down.

- Armrest wobble correction.

- Lumbar curve angle tweak.

- Caster hardness for floor type.

- Color shift to match brand guide.

| Review Area | What to Confirm | Typical Fix |

|---|---|---|

| Comfort | Seat density, back support | Adjust foam or mesh tension |

| Function | Mechanism smoothness | Grease, tolerance tweak |

| Aesthetics | Color and stitching | New dye lot or pattern |

| Packaging | Fit and protection | Add foam, change layout |

When do we confirm the order and start production?

You want speed but no surprises. You need a clean contract and a clear plan. I lock terms, book materials, and start the line.

We sign the contract with price, MOQ, lead time, and payment terms. You place the order. I buy materials, set the schedule, and prepare the assembly line.

I propose a timeline with buffers. I create a production Gantt. I share milestones: material arrival, pre-production sample, mid-line check, and finish date. You get weekly updates. You see photos and batch tests. This reduces risk and keeps the plan on track.

Contract essentials

- Final spec list and revision level.

- Unit price by style and color.

- MOQ and mixed loading plan.

- Payment terms and deposit.

- Lead time and liquidated damages.

Production plan

- Material booking and incoming QC.

- Pilot run for first 30–50 sets.

- Line setup and work instructions.

- Inline QC checkpoints and records.

- Final packing and carton tests.

| Milestone | Owner | Evidence |

|---|---|---|

| Deposit received | Buyer | Bank slip |

| Materials in | Factory | Photos, IQC report |

| Pilot run pass | Factory + Buyer | Video + checklist |

| Mid-line audit | Factory or 3rd party | Report |

| Final QC | Factory or 3rd party | AQL report |

How do we control quality before shipment?

You fear quality drift in big runs. You need proof. I use layered QC and open the doors to third-party checks.

We run incoming, in-process, and final inspections. You choose factory reports, third-party inspection, or a visit. We fix issues before shipping.

I follow clear AQL plans. I track defects by type and station. I audit packaging strength. I test function on samples from each batch. If you need BIFMA or RoHS, I coordinate lab tests and sample draws. I share data, not just words.

QC layers

- IQC: gas lift class, caster hardness, fabric color and rubs.

- IPQC: torque, fastener checks, function tests at station.

- OQC: random sample, full function and finish review.

- Carton: drop test, edge crush test.

- Compliance: BIFMA cycles, RoHS, and flame if needed.

Inspection choices

- Factory QC report with photos and videos.

- Third-party AQL inspection at our site.

- Live video call walk-through.

| Inspection Type | Speed | Cost | Independence |

|---|---|---|---|

| Factory report | Fast | Included | Internal |

| 3rd-party (e.g., SGS) | Medium | Extra | High |

| Client visit | Slow | Travel | Highest |

How do we ship, clear customs, and deliver?

You worry about shipping and paperwork. Chairs are bulky. Costs add up. I plan container loading, shipping terms, and documents so you land smoothly.

We book sea freight, optimize loading, and prepare documents. You clear customs on arrival and arrange local delivery. Then you start selling.

I suggest FOB or CIF based on your setup. I optimize carton sizes and mixed models for better load. I prepare all export papers. I guide your broker on HS codes and duty rates. If you need drop tests or barcodes for retail, I include them.

Shipping choices

- EXW2: you pick up at our factory.

- FOB: we deliver to port and load to vessel.

- CIF: we book sea freight and insurance to your port.

Documents we provide

- Commercial invoice and packing list.

- Bill of lading.

- Certificate of origin, if needed.

- Test and compliance reports.

- HS code advice and product specs.

| Term | Who Pays to Port | Who Pays Ocean | Risk Transfer |

|---|---|---|---|

| EXW | Buyer | Buyer | At factory gate |

| FOB | Seller to port | Buyer | Onboard vessel |

| CIF | Seller to destination port | Seller | At destination port arrival |

Conclusion

I take your idea, prove feasibility, confirm design, sample and refine, produce at scale, verify quality, ship, and land. You start selling with confidence.